Apprenticeship│Fond du Lac Campus

Maintenance Technician Apprenticeship

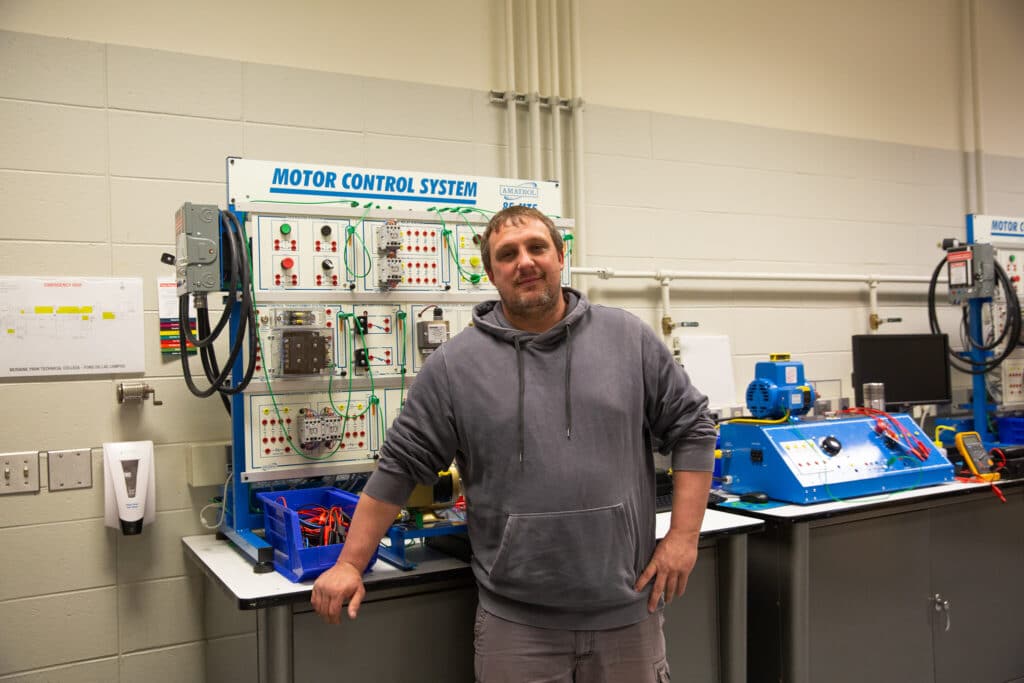

Gain on-the-job training and perfect a wide range of installation, manufacturing and maintenance skills with the Maintenance Technician Apprenticeship at Moraine Park Technical College.

Maintenance technicians perform tasks related to installation and repair of manufacturing, process and facility related equipment. Both mechanical and electrical skills are applied to preventative and predictive maintenance, equipment repairs and equipment enhancements.

What You’ll Learn

To succeed within an industrial working environment, maintenance technician apprentices will need to learn safety precautions, print reading, National Electrical Code, motor controls, programmable controllers, preventative and predictive practices and fluid power. This apprenticeship combines theory and hands-on instruction to each student enhancing the skills required for a career in the technical trades.

Work Description

Maintenance Technicians perform tasks to adjust, modify, repair and improve equipment and processes within an industrial environment. They also read blueprints, install hydraulic and pneumatic equipment and controls. Preventative maintenance, bearing diagnostics, mechanical drives and pump system repairs are additional tasks completed by Maintenance Technicians.

Maintenance Technicians will also perform electrical tasks such as troubleshooting with the use of a multimeter, oscilloscope and other testing equipment. They install conduit, electrical circuits, and electrical controls such as timers, relays, and variable speed drives. Utilizing a Programmable logic controllers (PLCs) is another technical skill that assists in troubleshooting and improving manufacturing equipment. Maintenance Technicians also perform machining, welding and other tasks using hand tools, mills and lathes.

For safety, Maintenance Technicians must understand the risks and hazards when working on industrial equipment. A practical understanding of OSHA is required in addition to referencing and understanding the National Electrical Code designed to protect persons and property from hazards arising from the use of electricity.

Potential careers include, but are not limited to, the following:

- Maintenance Technician

- Project/Design Technician

- Industrial Electrician

- Repair/Service Technician

Application Information

Apprentice students do not complete standard admissions with Moraine Park. Interested students should contact:

Tim Budda, Apprenticeship Training Representative

Phone: 262-335-5849

Email: timothy.budda@dwd.wisconsin.gov

Application Requirements

Applicants should be 18 years of age and submit an apprentice/employer application to the Bureau of Apprenticeship Standards. Applicants must have a high school diploma or equivalent and be physically able to perform required work practices safely.

Students are required to complete First Aid/CPR and Transition to Trainer classes.

Tuition Costs

The cost of your degree depends on a number of factors such as total credits required, textbooks and the financial aid you receive. Some programs have additional costs such as uniforms, technology and equipment.

Please refer to the Tuition & Fee Information for enrollment fee information.

Cost of Attendance

Cost of attendance (sometimes referred to as the “sticker price”) is the maximum amount of money it costs to attend college for one year and is used to determine your financial aid offering.

While attending Moraine Park during the 2024-25 school year, your estimated cost of attendance for one full year includes tuition of $4,462 (15 credits for fall and spring semester), fees of $338, food and housing of $3,008 (if living with parents, $9,147 if living on your own), books and supplies of $1,465, personal expenses of $3,608, and transportation of $4,017 for a total of $17,002. Your direct costs (those costs paid directly to the college) include tuition & fees. The indirect costs (costs not paid to the college) can vary from individual to individual and your own personal needs.

Requirements

Applicants should be 18 years of age and submit an apprentice/employer application to the Bureau of Apprenticeship Standards. Applicants must have a high school diploma or equivalent and be physically able to perform required work practices safely.

Students are required to complete First Aid/CPR and Transition to Trainer classes.

Training Period

The Maintenance Technician Apprenticeship consists of five years at 10,144 hours, of which 876 hours is spent in paid-related classroom instruction. First Aid and CPR are completed during the first 12 months of the contract with the Transition to Trainer course in the final year of the apprenticeship.

Working Conditions

Maintenance technicians require a moderate level of physical strength. They must frequently stand, squat or kneel for long periods and work in cramped or uncomfortable positions. Since much of their work is indoors, maintenance technicians are less exposed to inclement weather than most other trade workers.

Tools and Equipment

Maintenance Technicians usually provide their own tools, including screwdrivers, pliers, sockets sets, adjustable wrenches and hammers. Employers generally provide heavier tools such as grinders, air tools, test meters and power tools.

Transfer Opportunities

Contact Kim Spartz at (920) 924-3217 or kspartz@morainepark.edu to discuss transfer opportunities.

Journeyworkers can earn a degree customized to their interests with the Technical Studies – Journeyworker Associate of Applied Science degree at Moraine Park Technical College.

If you want to learn more about apprenticeships in Wisconsin, visit https://dwd.wisconsin.gov/apprenticeship/.

High school dual credit provides high school students the opportunity to earn college credit while in high school, without leaving their high school classroom. The courses are taught by certified high school instructors using technical college curriculum, grading policies and textbooks.

Has previous life experience already helped you build knowledge and skills applicable to your studies? Applying previously earned credits to a program of study can save you both time spent in the classroom and money spent on tuition and fees.

Transferring here is easy! You can transfer in prior college work by submitting official college transcripts or get a free transcript review.

Financial Aid is provided to aid eligible associate degree and technical diploma programs with 28 credits or more. Processing can take 6-8 weeks after a student’s completed Free Application for Federal Student Aid (FAFSA) is received.

Financial Aid is available for associate degree and technical diploma programs (those that are 2 semesters in length and typically with 28 credits or more). Processing can take 4-5 weeks after a student’s completed Free Application for Federal Student Aid (FAFSA) is received. Visit the Financial Aid page to learn more.

Our recruiters on any of the three campuses are ready to help you plan your future!